CNC Routing of a Non-Slip Spa Floor System Using Marine Decking Foam

CNC Routers provide a wide range of capabilities when it comes to manufacturing precision custom components from flat sheets. They are capable of cutting a variety of materials including wood, plastics, aluminum, and in this case, closed cell PE/EVA foam for the marine and spa industries.

Read on for an informative case study about how we used advanced CNC router and CAD/CAM technology to create the perfect non-slip floor for a client in the spa industry.

Problem

MF Engineering was tasked with building a non-slip flooring system for use in indoor and outdoor spas, swimming pools, and hot tubs. In order to develop an optimal solution, we had to overcome three challenges:

- We had to determine the best method of securing foam sheets to the router table to ensure stability during the machining process

- We had to maximize material usage and minimize material waste

- We had to set precise tooling speeds to create optimal cutting conditions that worked under the best possible cycle times

This customer chose MF Engineering because they were familiar with our experience in producing custom marine deck foam for boating applications, and they wanted us to repeat our success in a similar application.

Solution

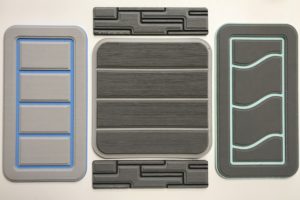

Our team was able to overcome these challenges through the use of CNC routing, allowing us to create a product to the following specifications:

- Tolerances of ±.0625”

- Ability to work in spas, pools, hot tubs

- Good performance on visual inspection tests

- On-time delivery of 50 units

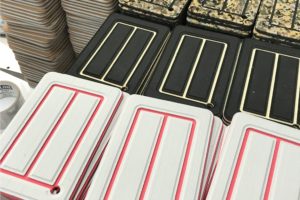

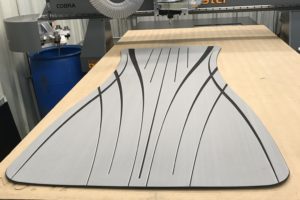

CNC routing provided MF Engineering with the best possible outcome. We worked with EVA marine foam equipped with an adhesive backing for semipermanent fixturing.

We also used a drag-knife, used for fine praise line soft material cutting, to shape the outer profile of the foam decking. We provided finished products within a one-week cycle time, and the product quality exceeded our client’s expectations.

Working With MF

Our engineers are highly committed to finding high-precision solutions using CNC and additive manufacturing techniques. We strive to meet or exceed all our customers’ expectations by filling large-volume orders within the shortest possible cycle times.

If you would like to learn more about our manufacturing services, feel free to contact us today.