Machining Services

Computer numerical control (CNC) machining is a subtractive manufacturing process that uses digitally controlled cutting tools to remove material from a workpiece per a specified design. A CNC machine utilizes computer-generated program files which provide a set of instructions that control the movement of the machine tools across the workpiece.

Due to its automated nature, CNC machining offers a higher degree of repeatability, precision, and flexibility compared with manually controlled manufacturing methods. These benefits have made CNC machining an increasingly popular solution for a growing number of industries.

CNC Machining Services at MF Engineering

At MF Engineering, we utilize several different CNC machining operations to produce a range of high-precision components efficiently. Our specific capabilities include:

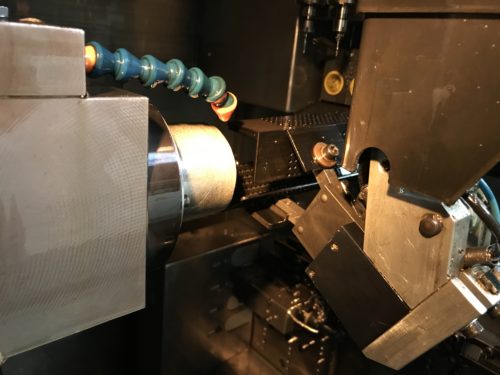

CNC Swiss machining. A CNC Swiss machine is an automatic lathe with a specialized design that enables greater stability of the workpiece as it is machined. A guide bushing holds the workpiece tightly in place as it meets the cutting tools, resulting in minimized deflections and vibrations. Swiss machining is ideal for parts requiring high levels of accuracy and extremely tight tolerances. MF Engineering produces Swiss-machined precision shafts used for a variety of printing and rolling applications.

CNC turn-milling. With CNC turn-milling, a combination of turning tools and milling cutters are used to machine a workpiece as it rotates around its center point. By combining turning and milling techniques in a single setup, turn-milling produces multiple features in a shorter amount of time than traditional turning or milling alone. This process can fabricate parts with complex geometries since the movement of the milling cutter can be coordinated with the rotating workpiece to achieve atypical shapes or designs.

CNC milling. The CNC milling process utilizes rotary cutters to remove material from a workpiece selectively. The workpiece is typically fed into the cutting tools by the CNC machine, and the tools move along multiple axes to create unique shapes or details.

CNC routing. A CNC router is a computer-operated cutting machine similar to the hand-held routers commonly used to cut steel, wood, composites, glass, and other materials. Using CNC technology, the tool moves across a workpiece along a series of axes to perform the cutting action. CNC routers operate at high speeds and allow for increased efficiencies and waste reductions.

Value-Added Services

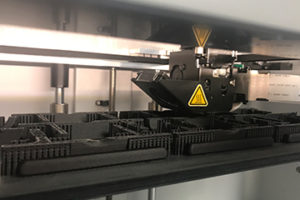

At MF Engineering, we strive to provide our diverse customer base with access to a variety of services and products that can be enhanced or personalized through value-added services. To this end, we are continually expanding our capabilities with the latest in innovative manufacturing technologies. For example, we offer rapid prototyping through 3D printing to help companies quickly and inexpensively transform new ideas into actual testable models.

At MF Engineering, we strive to provide our diverse customer base with access to a variety of services and products that can be enhanced or personalized through value-added services. To this end, we are continually expanding our capabilities with the latest in innovative manufacturing technologies. For example, we offer rapid prototyping through 3D printing to help companies quickly and inexpensively transform new ideas into actual testable models.

With our diverse range of in-house fixturing and tooling, we provide customized 3D FPM printing services and capabilities for a wide range of projects. Our current setup allows us to accommodate project runs and production volumes from 1–500 items. We offer two printer options to help us meet the specific printing needs of each customer.

In addition to our 3D printing capabilities, we also offer other in-house value-added services to make sure each product is manufactured and prepared according to exact specifications. These include:

- Assembly

- Broaching

- Part marking

- Dot Peening

- Vibratory Tumbling

For customers requiring additional services to finalize their project, we have built a network of trusted partners that can perform anodizing, passivation, plating, heat treatments, and more. By providing this outsourcing capability, we help customers keep their supply chain management as straightforward as possible while delivering products in the exact form requested.

Advantages of CNC Machining

CNC machines have become a staple within the manufacturing industry for their ability to quickly, efficiently, and cost-effectively fabricate single prototypes to high production volumes. Using pre-programmed software to manipulate the actions of tools, CNC technology automates a variety of complex machining procedures, including milling, turning, grinding, routing, and lathing. Since the introduction of CNC machining in the late 1960s, continual improvements to the speed, efficiency, and accuracy of this technology have made it the dominant machining method in today’s manufacturing world.

A few of the benefits gained by using CNC machining include:

- Precision and consistency. Because it is an automated process, CNC machining virtually eliminates human error to facilitate unparalleled levels of precision and repeatability. A CNC machine can replicate a programmed design across any number of items with exceptional accuracy.

- Productivity. CNC machines perform a complex series of actions with minimal supervision, meaning that the equipment can be programmed to continue operating outside of regular business hours. This capability can vastly increase output rates and overall productivity.

- Flexibility. Reprogramming CNC machine software for different parts or designs is typically simple, quick, and inexpensive, making it easier to accommodate design changes or demand shifts.

- Complexity. CNC machines may utilize different axes or tool orientations to perform complex and challenging operations. The complex, multidimensional parts produced with CNC machining would be difficult or impossible to replicate through manual fabrication methods.

Advanced CNC Machining Capabilities From MF Engineering

CNC machining has played an essential role in advancing manufacturing. By automating the machining process, it offers a quicker and more cost-effective way to fabricate highly accurate prototypes and end-use products. Following a set of detailed programming instructions facilitates precise control of the movement of the tools to produce parts with complex geometries and intricate design features.

MF Engineering is a family-owned and operated business specializing in the production of high-precision miniature- to medium-sized components for industries with strict quality standards and tight tolerance requirements. Our CNC machining capabilities include Swiss turning, turn-milling, milling, and routing to exact specifications. We offer a wide range of materials for CNC machining as well. As an extension of our capabilities, we also offer a range of value-added services to further enhance and optimize each product. We are committed to fully satisfying the unique needs of each customer by continually improving our operations and embracing new technologies.

To learn more about our CNC machining capabilities and value-added services, please contact us today or request a quote.